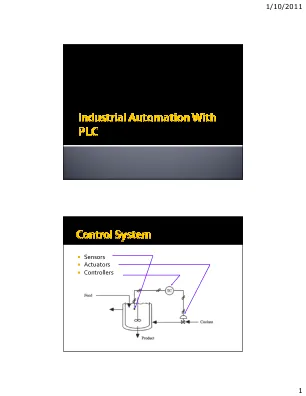

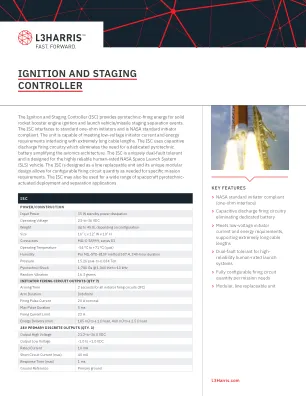

Components of Fatigue Test Controller Manjula B K EEE Department BMSIT&M Abstract: This paper describes about the development of computer controlled single channel controller used in servo hydraulic test system for fatigue testing of materials. The closed loop control obtained with load cell and LVDT which provides an electrical signal to the controller proportional to the mechanical position of the actuator or load exerted by it. The electrical signal is passed through signal conditioning circuitry for amplification of the signal which is fed to the servo-controller to generate an error signal. The feedback mode whether in stroke (LVDT) or Load mode is compared with respective set points using a differential amplifier. Add -on boards of digital to analog converter is used to convert the set-points which are in digital form to analog value. The operations of the controller are displayed on the console of the computer. Keywords: Fatigue test, Controller DAC,ADC, Load mode and stroke mode 1. Introduction Fatigue testing is critical requirement of aircraft to determine the life span of the aircraft. A fatigue test helps determine a material's ability to withstand cyclic fatigue loading conditions. By design, a material is selected to meet or exceed service loads that are anticipated in fatigue testing applications. Cyclic fatigue tests produce repeated loading and unloading in tension, compression, bending, torsion or combinations of these stresses. Fatigue tests are commonly loaded in tension – tension, compression – compression and tension into compression and reverse. To perform a fatigue test a sample is loaded into a fatigue tester or fatigue test machine and loaded using the pre- determined test stress, then unloaded to either zero load or an opposite load[1]. This cycle of loading and unloading is then repeated until the end of the test is reached. The test may be run to a pre-determined number of cycles or until the sample has failed depending on the parameters of the test[2]. The purpose of a fatigue test usually is to determine the lifespan that may be expected from a material subjected to cyclic loading, however fatigue strength and crack resistance are commonly sought values as well. The fatigue life of a material is the total number of cycles that a material can be subjected to under a single loading scheme. A fatigue test is also used for the determination of the maximum load that a sample can withstand for a specified number of cycles. All of these characteristics are extremely important in any industry where a material is subject to fluctuating instead of constant forces. Types of fatigue tests: There are several common types of fatigue testing as well as two common forms: load controlled high cycle and strain controlled low cycle fatigue. A high cycle test tends to be associated with loads in the elastic regime and low cycle fatigue tests generally involve plastic deformations. Types of materials for fatigue tests Most of the materials may experience fatigue in one way or another during the lifespan of their application. However, in applications where fatigue is a factor it is common to find components made from metals or composites. These materials have a higher fatigue limit than others because of

疲劳试验控制器的组成部分

主要关键词