机构名称:

¥ 1.0

When a submarine cable is laid, it needs to be loaded onto a cable laying ship, which has a finite hold capacity. So, the thinner the submarine cable, the more cable length the ship can carry. For a trans-oceanic cable, this is a critical economic factor for the cable deployment cost, and for this reason the industry prefers a 17-mm cable for deep water. 21-mm cable designs also exist, but a cable laying ship can carry 30% less length of 21-mm cable vs. 17-mm cable. In a major project, this would require ships to return to port, load more cable, and then go back and retrieve the end of the cable they just laid – and to potentially repeat this process several times.

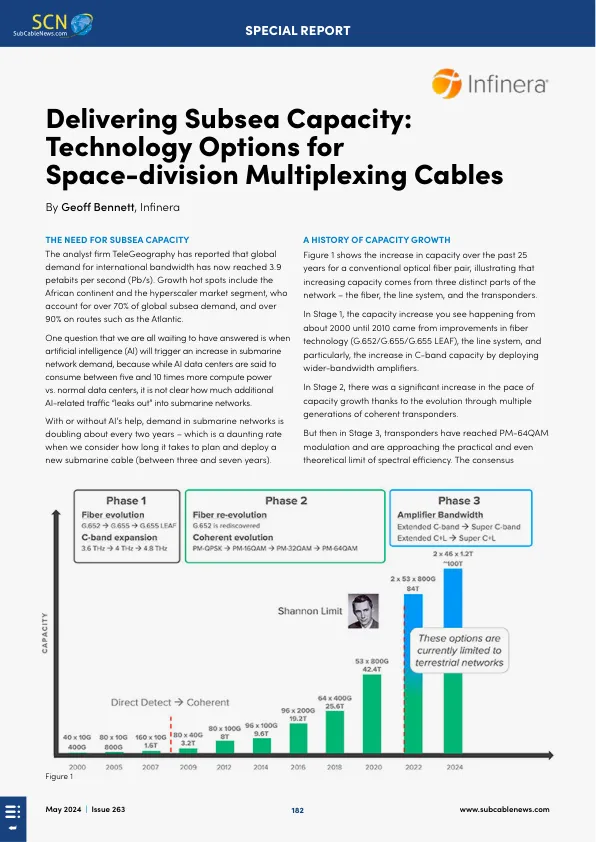

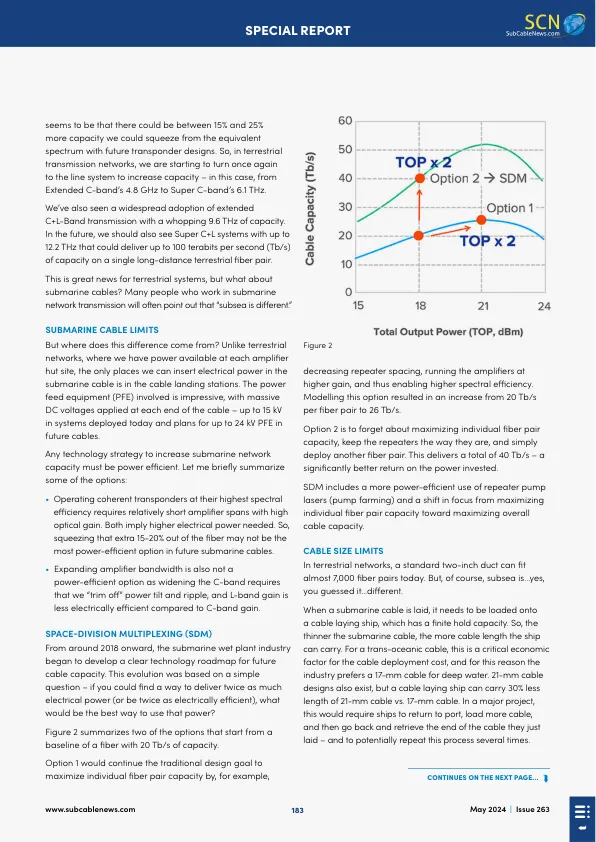

Delivering Subsea Capacity: Technology Options for ...