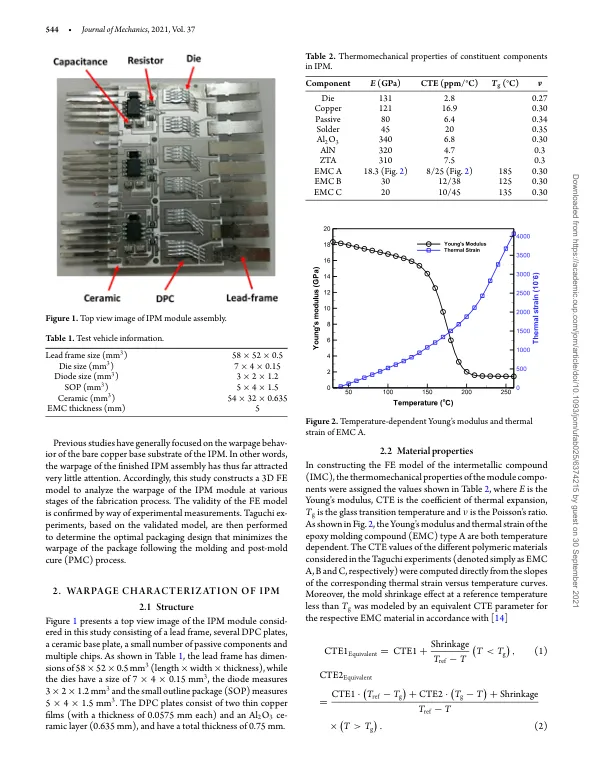

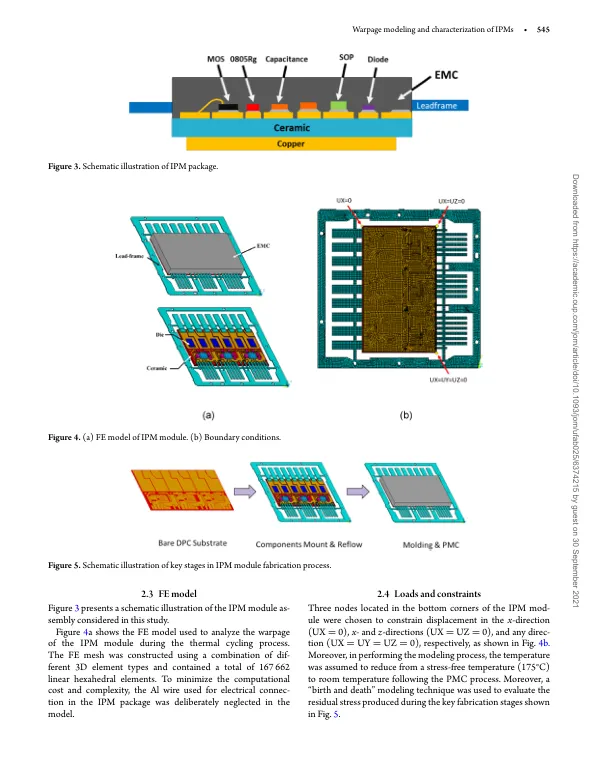

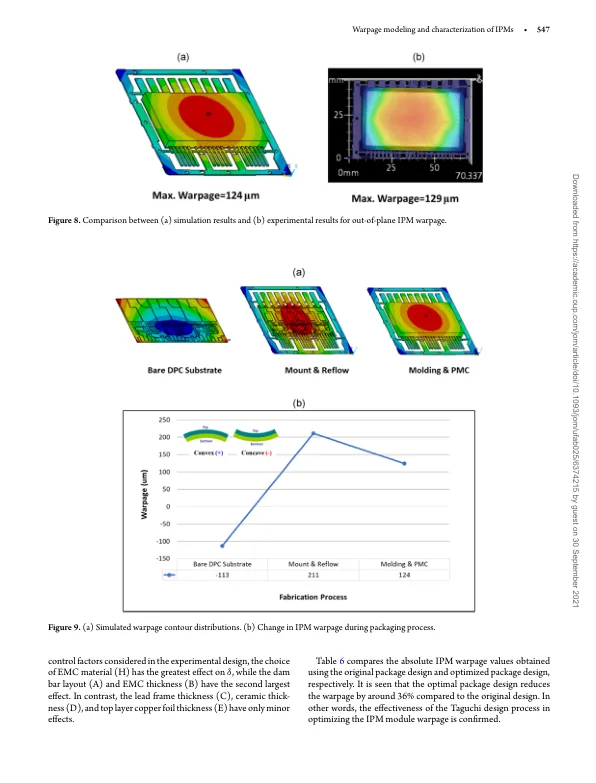

Intelligent power modules (IPMs) are widely used in the electric vehicle (and hybrid electric vehicle industry nowadays due to their high power densityandabilitytointegratemultiplecomponentswithinasinglepackage.However,thereliabilityofIPMsisseverelydegradedbythesubstrate warpage effect produced during the packaging process.因此,本研究开发了一个计算模型,以分析包装过程的各个阶段IPM组装的经线。通过比较直接镀铜底物的经线的数值结果与实验观察结果来确认模拟模型的有效性。Taguchi experiments are then performed to examine the effects of eight control factors on the IPM package warpage following the post-mold cure (PMC) process, namely (1) the dam bar layout, (2) the epoxy molding compound (EMC) thickness, (3) the lead frame thickness, (4) the ceramic thickness, (5) the bottom layer Cu foil thickness, (6) the top layer Cu foil thickness, (7)陶瓷材料类型和(8)EMC材料类型。最后,Taguchi分析结果用于确定最大程度地减少POST-PMC软件包的经线的最佳包装设计。

智能功率模块(IPMS)的扭曲建模和表征

主要关键词